October 13, 2025

Too many rolls? Too few pretzels? A glance at the display case at closing time shows that producing the right amount of baked goods daily isn’t so simple. The challenge: Enough sales, minimal returns – without sellouts and unhappy customers. Here’s how it works.

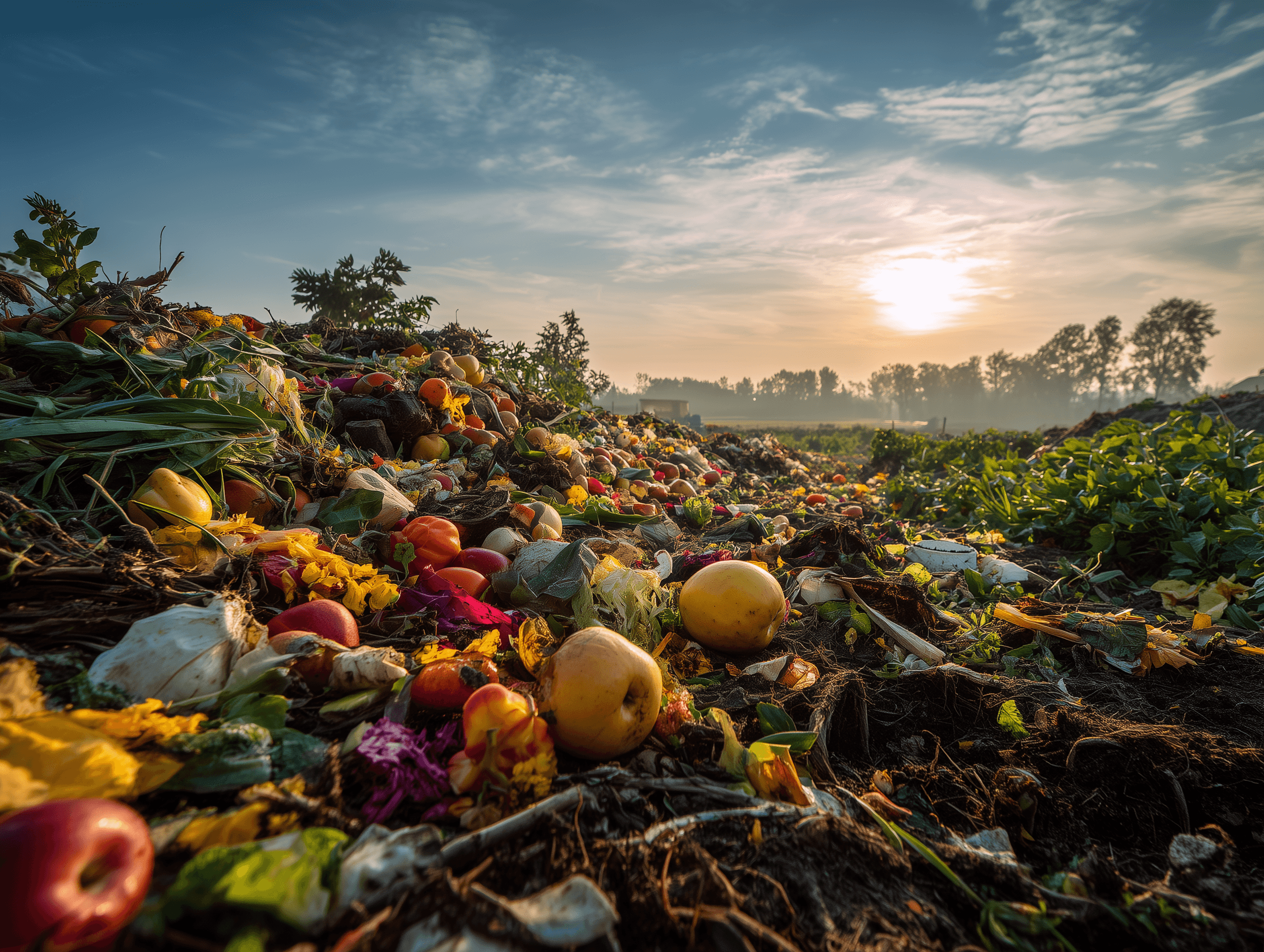

Germans throw away about 1.7 million tons of baked goods each year, as shown by a study by the Worldwide Fund for Nature (WWF). About one third of this waste comes from bakery returns.

Returned baked goods are part of a global issue

This problem is not only economic but also ethical, ecological, and social. After all, every wasted food item consumes valuable resources like water, energy, and farmland – resources that are urgently needed elsewhere.

The great return dilemma

Why is it so difficult to determine the optimal return rate? Because bakers face a major dilemma daily in their shops: Customers expect full shelves, absolute freshness, and optimal quality. Contracts oblige bakeries in supermarkets and discounters to offer a wide selection until closing time. To ensure this, they must accept vast amounts of returns.

Although there are no official studies for Germany, estimates and industry data suggest average return rates are around 15 percent, and even higher in some cases.

Specifically, this means a bakery with 20 branches records six-figure losses annually. They return about 750,000 rolls each year, corresponding to lost revenue of about €225,000.

The good news, however, is that even a small optimization can significantly reduce these losses. Reducing the return rate by just one percentage point saves raw material costs of €7,000 a year – and leads to savings in personnel, energy, and machinery.

Three simple steps: How to optimize your returns

To optimize returns, follow these three steps.

Capture the current status

In the first step, capture your current status by measuring and analyzing all losses of bread and baked goods. You’ll find: The biggest losses often occur the day before – directly in the ordering process. The three most common causes of high return rates are:

Insufficient information base for orders

Lack of expertise among sales staff

Missing information on key figures in the branches

Review and adjust processes

In the second step, review and adjust your existing processes. Identify which factors have the most significant impact on your returns – such as weather, weekdays, holidays – and adjust your orders accordingly in the future.

Conduct an ABC analysis for this:

Focus should be on the main assortment, ensuring it’s sufficiently available to customers until closing time. Specifically, this means:

The A-items, which generate about 75% of turnover with 25 to 30 products, should be available until closing. Set the return rate between ten and 15 percent here to achieve optimal sales and avoid sellouts.

B and C items should only be produced in small quantities and sold promptly.

Based on the ABC analysis, you can also reduce your assortment. A-items with low contribution margin should not be as prominently placed as expensive snack items.

Get smart support

In the third step, take a look at the smart solutions the market offers bakeries: Intelligent forecasts ensure that future orders are based on historical data rather than gut feeling.

Delicious Data's AI forecast solution supports branches daily in the ordering process and makes suggestions for optimal quantities. It naturally takes factors like holidays and weather into account. The result?

A 100% automated ordering process

30 percent fewer returns

20 percent less sellouts

Staff are also supported by an automated to-do list. This way, employees can focus again on what really matters: Baking. And customers.

Curious? Schedule an appointment with us.